New SHXLife enamelled copper wire offers:

- Durability: 500x life time* under partial discharge

- Design flexibility: Enables smaller safety margins

- Increased efficiency: Increased copper fill factor due to reduced layer thicknesses

- Economy: Makes 800V+ solutions more cost-effective

- Excellent quality: Manufactured according to recognized SHWire 'Industry 4.0+' process technology

In the race for more power, faster charging times and greater efficiency, SHWire proves with the new SHXLife that maximum service life is not necessarily contradictory to ambitious motor design and cost awareness.

Thanks to a unique combination of materials in the coating system, the limits of service life under partial discharge have been shifted for the first time into areas that make it possible to allow partial discharge in the design. This opens up unprecedented options in the design of electric motors in the 800V+ environment.

Dr. Andreas Levermann, Managing Director at SHWire, recapitulates:

" SHXLife literally gives designers wings: thanks to the durability of SHXLife, partial discharges in 800V+ applications no longer have to be categorically ruled out. SHXLife thus facilitates flexibility for our customers to reduce layer thicknesses and increase the copper fill factor, which is important for efficiency. Our solution is also commercially interesting as it is based on established insulation systems."

Electric vehicles with 800V+ systems - challenges for the electrical insulation system due to partial discharges

In order to be able to charge battery electric vehicles (BEV) with higher power more quickly, future systems will increasingly rely on voltage levels of 800 V and more. In addition, modern power switches in the inverter between the battery and electric motor are based on silicon carbide semiconductors (SiC power module). These place very high demands on the entire electrical insulation system of the electric motor, as faster pulses can cause potential differences in neighbouring windings as well as interference up to 2.5 times the wave propagation height. This process, also known as partial discharge, triggers an avalanche of charge carriers that gradually erodes the insulating material and leads to the destruction of the insulation system (total breakdown) after a foreseeable period of time.

State of technology - limits of coating thickness optimization

In current practice, this problem is countered by increasing the layer thickness of enamelled wires in order to compensate for the increasing voltage load on the insulation system and prevent the occurrence of partial discharges. However, this approach reaches its limits, as very high layer thicknesses (>150µm) are required which reduce the utilization of winding space. The result is a reduction in the performance of the system and therefore the efficiency of the drive.

The SHWire alternative: SHXLife enables an unrivalled 500 times the service life under partial discharges

SHXLife takes a different approach here. Thanks to an innovative modification of the enamel system, including optimization of the relative permittivity of the individual enamel layers, the enamelled copper wire manufactured using established processes is able to withstand the damage mechanism of partial discharge inception voltage for significantly longer. This means that partial discharge does not lead to total breakdown within a very short time. Compared to conventional wires with comparable standard polymers, the new SHXLife enamelled wire achieves a service life that is over 500 times longer.

Innovation SHXLife enables partial discharge in the construction

This offers designers of electric machines enormous design potential. Allowing a certain amount of partial discharge leads to new freedoms that can be used to reduce layer thicknesses and, conversely, increase the copper fill factor. The result is higher performance and efficiency for the demanding applications of electric mobility.

Unrivalled cost efficiency for 800V+ applications

Commercially, SHXLife offers immense cost potential in the electrical insulation system compared to extruded solutions and is based on existing insulation systems and processes of SHWire.

With SHXLife, SHWire is setting a new standard for the future of electric mobility and helping to successfully overcome the current technical and commercial challenges in electric mobility.

Do you have questions about our enameled copper wire for 800V+ e-mobility solutions SHXLife? Our sales manager will be happy to help you.

Jan Oderwald

Head of sales

+49-5281-988-125 j.oderwald@sh-wire.de

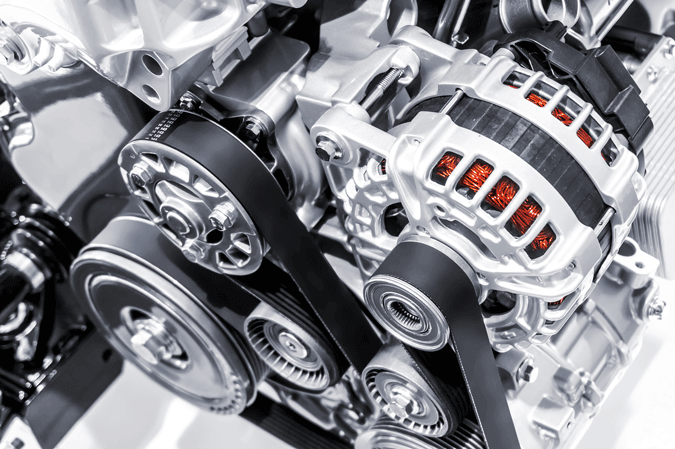

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)