Winding wire SHBond® WD210 Glide

- Enamelled round copper wire, thermoresistant,

selfbonding and self lubricating - Insulated with THEIC mod. polyesterimide

- plus polyamide-imide overcoat plus bonding layer

- Class 200

SHBond® WD210 Glide is a highly thermoresistant self-bonding enamelled copper wire of heat performance class N. With this wire the excellent resistance and insulation properties of SHTherm® 210 – Dualcoat are combined with the special application possibilities of an additional bonding layer which is based on mod. aromat. polyamide and which enables the production of heat bonded wire windings. Using this type of thermo-setting wire the heat bonding process is economic, as it can be executed within seconds and can support automatic processing. It is not harmful to the environment. Heat bonded windings show excellent thermal and mechanical stability and high resistance to climatic demands and many chemical agents. Sophisticated process technology and process setting ensure easy mouldability, good elongation and excellent insulation properties.

The final layer of varnish serves the purpose of providing a superior gliding surface, giving the wire excellent windability features at higher speeds, and enabling a higher filling factor plus reduced soiling of the winding machines. The reduced coefficient of friction helps to avoid damage to the wire during winding and thus maintains the insualtion properties of the wire.

Application

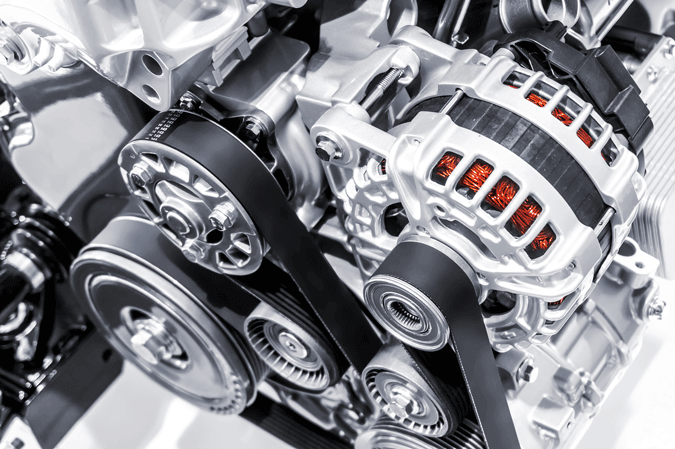

Drives for household appliances, pole windings, wire wound coils, power tools

Standards

IEC / DIN EN 60317-38

NEMA MW 102-C

Delivery forms

Grade 1: on request

Grade 2: on request

Technical data

Typical properties of enamelled round copper wire 0.500 mm, with insulation film grade 1B

| Property | Unit of measure | Set value | Actual value (typ.) |

|---|---|---|---|

| Overall diameter | mm | min. 0.541 - max. 0.568 | as set value |

| Bare wire diameter | mm | 0.495-0.505 | as set value |

| Adhesion (no cracks in film after winding) | mandrel diameter 0.500 mm | 1 x d / 10 % pre-elongation | |

| Scrape resistance | N | ≥ 3.950 | ≥ 7.500 |

| Pencil hardness | H | 3H - 5H | |

| Elongation at break | % | ≥ 28 | ≥ 38 |

| Coefficient of friction | µ | / | ≤ 0.110 |

|

(1) Due to the variety of individual applications we cannot make any generally binding commitments regarding the compatibility. We recommend testing compatibility with the materials being used. |

|||

| Property | Unit of measure | Set value | Actual value (typ.) |

|---|---|---|---|

| Temperature index TI | °C | 200 | 210 |

| Cut through temperature (pre-heated block) | °C | 320 | ≥ 360 |

| Dielectric loss factor (bending point) | (°C) (tan δ) | / | ≥ 140/185/240 |

| Heat shock at 220 °C (no cracks in varnish coat after winding) | mandrel diameter 1.120 mm | 1 x d / 10 % pre-elongation | |

| Bonding temperature | °C | 200 +/-2 | ≥ 210 |

|

(1) Due to the variety of individual applications we cannot make any generally binding commitments regarding the compatibility. We recommend testing compatibility with the materials being used. |

|||

| Property | Unit of measure | Set value | Actual value (typ.) |

|---|---|---|---|

| Dielectrical strength at RT | kV | ≥ 2.4 (twist) | ≥ 3 (cylinder) |

| High voltage discontiniuties 750V | ≤ 10 on 30 m | ≤ 7 on 100 m | |

| Electrical conductivity | MS/m | 58 - 59 | ≥ 58.5 |

|

(1) Due to the variety of individual applications we cannot make any generally binding commitments regarding the compatibility. We recommend testing compatibility with the materials being used. |

|||

| Property | Set value | Actual value (typ.) |

|---|---|---|

| Pencil hardness (storage in standard solvent ½ h / 60 °C) | test methods unsuitable | / |

| Pencil hardness (storage in alcohol ½ h / 60 °C) | / | |

| Resistance to commercial impregnants^(1) | / | not applicable |

| Resistance to commercial refrigerants^(1) | / | limited |

| Resistance to commercial dry transformer oils^(1) | / | not recommended |

| Resistance to commercial hydraulic oils^(1) | / | no |

|

(1) Due to the variety of individual applications we cannot make any generally binding commitments regarding the compatibility. We recommend testing compatibility with the materials being used. |

||

With the digital magnet wire slide rule we have brought the well-known and popular handy tool from the desk to the desktop. Simply enter the desired nominal wire diameter via the input field or use the slider. At a glance you will find useful information on enamelled copper and aluminium wires based on IEC 60317-0-1.

- 0.030 mm

- 0.040 mm

- 0.045 mm

- 0.050 mm

- 0.053 mm

- 0.056 mm

- 0.060 mm

- 0.063 mm

- 0.067 mm

- 0.071 mm

- 0.075 mm

- 0.080 mm

- 0.085 mm

- 0.090 mm

- 0.095 mm

- 0.100 mm

- 0.106 mm

- 0.112 mm

- 0.118 mm

- 0.125 mm

- 0.132 mm

- 0.140 mm

- 0.150 mm

- 0.160 mm

- 0.170 mm

- 0.180 mm

- 0.190 mm

- 0.200 mm

- 0.212 mm

- 0.224 mm

- 0.236 mm

- 0.250 mm

- 0.265 mm

- 0.280 mm

- 0.300 mm

- 0.315 mm

- 0.335 mm

- 0.355 mm

- 0.375 mm

- 0.400 mm

- 0.425 mm

- 0.450 mm

- 0.475 mm

- 0.500 mm

- 0.530 mm

- 0.560 mm

- 0.600 mm

- 0.630 mm

- 0.670 mm

- 0.710 mm

- 0.750 mm

- 0.800 mm

- 0.850 mm

- 0.900 mm

- 0.950 mm

- 1.000 mm

- 1.060 mm

- 1.120 mm

- 1.180 mm

- 1.250 mm

- 1.320 mm

- 1.400 mm

- 1.500 mm

- 1.600 mm

- 1.700 mm

- 1.800 mm

- 1.900 mm

- 2.000 mm

- 2.120 mm

- 2.240 mm

- 2.360 mm

- 2.500 mm

- 2.650 mm

- 2.800 mm

- 3.000 mm

- 3.150 mm

- 3.350 mm

- 3.550 mm

- 3.750 mm

- 4.000 mm

- 4.250 mm

- 4.500 mm

- 4.750 mm

- 5.000 mm

| Conductor nominal Ø | 0.030 | mm | |

| Conductor cross section | 0.001 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.002 | kg/km | |

| Copper | Resistance min. | 21.765 | Ω/m |

| Resistance max. | 26.601 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.006 | kg/km | |

| Ø | Conductor min. | - | mm |

| Conductor max. | - | mm | |

| Enamelled grade 1 min. | 0.033 | mm | |

| Enamelled grade 1 max. | 0.037 | mm | |

| Enamelled grade 2 min. | 0.038 | mm | |

| Enamelled grade 2 max. | 0.041 | mm | |

| Conductor nominal Ø | 0.040 | mm | |

| Conductor cross section | 0.001 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.003 | kg/km | |

| Copper | Resistance min. | 12.379 | Ω/m |

| Resistance max. | 14.827 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.011 | kg/km | |

| Ø | Conductor min. | - | mm |

| Conductor max. | - | mm | |

| Enamelled grade 1 min. | 0.044 | mm | |

| Enamelled grade 1 max. | 0.049 | mm | |

| Enamelled grade 2 min. | 0.050 | mm | |

| Enamelled grade 2 max. | 0.054 | mm | |

| Conductor nominal Ø | 0.045 | mm | |

| Conductor cross section | 0.002 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.004 | kg/km | |

| Copper | Resistance min. | 9.781 | Ω/m |

| Resistance max. | 11.715 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.014 | kg/km | |

| Ø | Conductor min. | - | mm |

| Conductor max. | - | mm | |

| Enamelled grade 1 min. | 0.050 | mm | |

| Enamelled grade 1 max. | 0.055 | mm | |

| Enamelled grade 2 min. | 0.056 | mm | |

| Enamelled grade 2 max. | 0.061 | mm | |

| Conductor nominal Ø | 0.050 | mm | |

| Conductor cross section | 0.002 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.005 | kg/km | |

| Copper | Resistance min. | 7.9224 | Ω/m |

| Resistance max. | 9.4894 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.018 | kg/km | |

| Ø | Conductor min. | - | mm |

| Conductor max. | - | mm | |

| Enamelled grade 1 min. | 0.055 | mm | |

| Enamelled grade 1 max. | 0.060 | mm | |

| Enamelled grade 2 min. | 0.061 | mm | |

| Enamelled grade 2 max. | 0.066 | mm | |

| Conductor nominal Ø | 0.053 | mm | |

| Conductor cross section | 0.002 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.006 | kg/km | |

| Copper | Resistance min. | 7.0509 | Ω/m |

| Resistance max. | 8.4456 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.020 | kg/km | |

| Ø | Conductor min. | - | mm |

| Conductor max. | - | mm | |

| Enamelled grade 1 min. | 0.059 | mm | |

| Enamelled grade 1 max. | 0.064 | mm | |

| Enamelled grade 2 min. | 0.065 | mm | |

| Enamelled grade 2 max. | 0.070 | mm | |

| Conductor nominal Ø | 0.056 | mm | |

| Conductor cross section | 0.002 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.007 | kg/km | |

| Copper | Resistance min. | 6.3157 | Ω/m |

| Resistance max. | 7.5649 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.022 | kg/km | |

| Ø | Conductor min. | - | mm |

| Conductor max. | - | mm | |

| Enamelled grade 1 min. | 0.062 | mm | |

| Enamelled grade 1 max. | 0.067 | mm | |

| Enamelled grade 2 min. | 0.068 | mm | |

| Enamelled grade 2 max. | 0.074 | mm | |

| Conductor nominal Ø | 0.060 | mm | |

| Conductor cross section | 0.003 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.008 | kg/km | |

| Copper | Resistance min. | 5.5017 | Ω/m |

| Resistance max. | 6.5899 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.025 | kg/km | |

| Ø | Conductor min. | - | mm |

| Conductor max. | - | mm | |

| Enamelled grade 1 min. | 0.066 | mm | |

| Enamelled grade 1 max. | 0.072 | mm | |

| Enamelled grade 2 min. | 0.073 | mm | |

| Enamelled grade 2 max. | 0.079 | mm | |

| Conductor nominal Ø | 0.063 | mm | |

| Conductor cross section | 0.003 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.008 | kg/km | |

| Copper | Resistance min. | 4.9902 | Ω/m |

| Resistance max. | 5.9772 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.028 | kg/km | |

| Ø | Conductor min. | - | mm |

| Conductor max. | - | mm | |

| Enamelled grade 1 min. | 0.069 | mm | |

| Enamelled grade 1 max. | 0.076 | mm | |

| Enamelled grade 2 min. | 0.077 | mm | |

| Enamelled grade 2 max. | 0.083 | mm | |

| Conductor nominal Ø | 0.067 | mm | |

| Conductor cross section | 0.004 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.010 | kg/km | |

| Copper | Resistance min. | 4.4121 | Ω/m |

| Resistance max. | 5.2848 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.031 | kg/km | |

| Ø | Conductor min. | 0.064 | mm |

| Conductor max. | 0.070 | mm | |

| Enamelled grade 1 min. | 0.074 | mm | |

| Enamelled grade 1 max. | 0.080 | mm | |

| Enamelled grade 2 min. | 0.081 | mm | |

| Enamelled grade 2 max. | 0.088 | mm | |

| Conductor nominal Ø | 0.071 | mm | |

| Conductor cross section | 0.004 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.011 | kg/km | |

| Copper | Resistance min. | 3.9290 | Ω/m |

| Resistance max. | 4.7061 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.035 | kg/km | |

| Ø | Conductor min. | 0.068 | mm |

| Conductor max. | 0.074 | mm | |

| Enamelled grade 1 min. | 0.078 | mm | |

| Enamelled grade 1 max. | 0.084 | mm | |

| Enamelled grade 2 min. | 0.085 | mm | |

| Enamelled grade 2 max. | 0.091 | mm | |

| Conductor nominal Ø | 0.075 | mm | |

| Conductor cross section | 0.004 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.012 | kg/km | |

| Copper | Resistance min. | 3.5471 | Ω/m |

| Resistance max. | 4.2346 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.039 | kg/km | |

| Ø | Conductor min. | 0.072 | mm |

| Conductor max. | 0.078 | mm | |

| Enamelled grade 1 min. | 0.082 | mm | |

| Enamelled grade 1 max. | 0.089 | mm | |

| Enamelled grade 2 min. | 0.090 | mm | |

| Enamelled grade 2 max. | 0.095 | mm | |

| Conductor nominal Ø | 0.080 | mm | |

| Conductor cross section | 0.005 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.014 | kg/km | |

| Copper | Resistance min. | 3.1326 | Ω/m |

| Resistance max. | 3.7025 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.045 | kg/km | |

| Ø | Conductor min. | 0.077 | mm |

| Conductor max. | 0.083 | mm | |

| Enamelled grade 1 min. | 0.087 | mm | |

| Enamelled grade 1 max. | 0.094 | mm | |

| Enamelled grade 2 min. | 0.095 | mm | |

| Enamelled grade 2 max. | 0.101 | mm | |

| Conductor nominal Ø | 0.085 | mm | |

| Conductor cross section | 0.006 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.015 | kg/km | |

| Copper | Resistance min. | 2.7867 | Ω/m |

| Resistance max. | 3.2648 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.051 | kg/km | |

| Ø | Conductor min. | 0.082 | mm |

| Conductor max. | 0.088 | mm | |

| Enamelled grade 1 min. | 0.093 | mm | |

| Enamelled grade 1 max. | 0.100 | mm | |

| Enamelled grade 2 min. | 0.101 | mm | |

| Enamelled grade 2 max. | 0.107 | mm | |

| Conductor nominal Ø | 0.090 | mm | |

| Conductor cross section | 0.006 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.017 | kg/km | |

| Copper | Resistance min. | 2.4951 | Ω/m |

| Resistance max. | 2.9003 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.057 | kg/km | |

| Ø | Conductor min. | 0.087 | mm |

| Conductor max. | 0.093 | mm | |

| Enamelled grade 1 min. | 0.098 | mm | |

| Enamelled grade 1 max. | 0.105 | mm | |

| Enamelled grade 2 min. | 0.106 | mm | |

| Enamelled grade 2 max. | 0.113 | mm | |

| Conductor nominal Ø | 0.095 | mm | |

| Conductor cross section | 0.007 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.019 | kg/km | |

| Copper | Resistance min. | 2.2470 | Ω/m |

| Resistance max. | 2.5936 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.063 | kg/km | |

| Ø | Conductor min. | 0.092 | mm |

| Conductor max. | 0.098 | mm | |

| Enamelled grade 1 min. | 0.103 | mm | |

| Enamelled grade 1 max. | 0.111 | mm | |

| Enamelled grade 2 min. | 0.112 | mm | |

| Enamelled grade 2 max. | 0.119 | mm | |

| Conductor nominal Ø | 0.100 | mm | |

| Conductor cross section | 0.008 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.021 | kg/km | |

| Copper | Resistance min. | 2.0342 | Ω/m |

| Resistance max. | 2.3331 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.070 | kg/km | |

| Ø | Conductor min. | 0.097 | mm |

| Conductor max. | 0.103 | mm | |

| Enamelled grade 1 min. | 0.108 | mm | |

| Enamelled grade 1 max. | 0.117 | mm | |

| Enamelled grade 2 min. | 0.118 | mm | |

| Enamelled grade 2 max. | 0.125 | mm | |

| Conductor nominal Ø | 0.106 | mm | |

| Conductor cross section | 0.009 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.024 | kg/km | |

| Copper | Resistance min. | 1.8164 | Ω/m |

| Resistance max. | 2.0692 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.079 | kg/km | |

| Ø | Conductor min. | 0.103 | mm |

| Conductor max. | 0.109 | mm | |

| Enamelled grade 1 min. | 0.115 | mm | |

| Enamelled grade 1 max. | 0.123 | mm | |

| Enamelled grade 2 min. | 0.124 | mm | |

| Enamelled grade 2 max. | 0.132 | mm | |

| Conductor nominal Ø | 0.112 | mm | |

| Conductor cross section | 0.010 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.027 | kg/km | |

| Copper | Resistance min. | 1.6318 | Ω/m |

| Resistance max. | 1.8407 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.088 | kg/km | |

| Ø | Conductor min. | 0.109 | mm |

| Conductor max. | 0.115 | mm | |

| Enamelled grade 1 min. | 0.121 | mm | |

| Enamelled grade 1 max. | 0.130 | mm | |

| Enamelled grade 2 min. | 0.131 | mm | |

| Enamelled grade 2 max. | 0.139 | mm | |

| Conductor nominal Ø | 0.118 | mm | |

| Conductor cross section | 0.011 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.030 | kg/km | |

| Copper | Resistance min. | 1.4740 | Ω/m |

| Resistance max. | 1.6599 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.098 | kg/km | |

| Ø | Conductor min. | 0.115 | mm |

| Conductor max. | 0.121 | mm | |

| Enamelled grade 1 min. | 0.128 | mm | |

| Enamelled grade 1 max. | 0.136 | mm | |

| Enamelled grade 2 min. | 0.137 | mm | |

| Enamelled grade 2 max. | 0.145 | mm | |

| Conductor nominal Ø | 0.125 | mm | |

| Conductor cross section | 0.012 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.033 | kg/km | |

| Copper | Resistance min. | 1.3172 | Ω/m |

| Resistance max. | 1.4749 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.109 | kg/km | |

| Ø | Conductor min. | 0.122 | mm |

| Conductor max. | 0.128 | mm | |

| Enamelled grade 1 min. | 0.135 | mm | |

| Enamelled grade 1 max. | 0.144 | mm | |

| Enamelled grade 2 min. | 0.145 | mm | |

| Enamelled grade 2 max. | 0.154 | mm | |

| Conductor nominal Ø | 0.132 | mm | |

| Conductor cross section | 0.014 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.037 | kg/km | |

| Copper | Resistance min. | 1.1841 | Ω/m |

| Resistance max. | 1.3192 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.122 | kg/km | |

| Ø | Conductor min. | 0.129 | mm |

| Conductor max. | 0.135 | mm | |

| Enamelled grade 1 min. | 0.143 | mm | |

| Enamelled grade 1 max. | 0.152 | mm | |

| Enamelled grade 2 min. | 0.153 | mm | |

| Enamelled grade 2 max. | 0.162 | mm | |

| Conductor nominal Ø | 0.140 | mm | |

| Conductor cross section | 0.015 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.042 | kg/km | |

| Copper | Resistance min. | 1.0553 | Ω/m |

| Resistance max. | 1.1696 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.137 | kg/km | |

| Ø | Conductor min. | 0.137 | mm |

| Conductor max. | 0.143 | mm | |

| Enamelled grade 1 min. | 0.151 | mm | |

| Enamelled grade 1 max. | 0.160 | mm | |

| Enamelled grade 2 min. | 0.161 | mm | |

| Enamelled grade 2 max. | 0.171 | mm | |

| Conductor nominal Ø | 0.150 | mm | |

| Conductor cross section | 0.018 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.048 | kg/km | |

| Copper | Resistance min. | 0.9219 | Ω/m |

| Resistance max. | 1.0159 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.158 | kg/km | |

| Ø | Conductor min. | 0.147 | mm |

| Conductor max. | 0.153 | mm | |

| Enamelled grade 1 min. | 0.162 | mm | |

| Enamelled grade 1 max. | 0.171 | mm | |

| Enamelled grade 2 min. | 0.172 | mm | |

| Enamelled grade 2 max. | 0.182 | mm | |

| Conductor nominal Ø | 0.160 | mm | |

| Conductor cross section | 0.020 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.054 | kg/km | |

| Copper | Resistance min. | 0.8122 | Ω/m |

| Resistance max. | 0.8906 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.179 | kg/km | |

| Ø | Conductor min. | 0.157 | mm |

| Conductor max. | 0.163 | mm | |

| Enamelled grade 1 min. | 0.172 | mm | |

| Enamelled grade 1 max. | 0.182 | mm | |

| Enamelled grade 2 min. | 0.183 | mm | |

| Enamelled grade 2 max. | 0.194 | mm | |

| Conductor nominal Ø | 0.170 | mm | |

| Conductor cross section | 0.023 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.061 | kg/km | |

| Copper | Resistance min. | 0.7211 | Ω/m |

| Resistance max. | 0.7871 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.202 | kg/km | |

| Ø | Conductor min. | 0.167 | mm |

| Conductor max. | 0.173 | mm | |

| Enamelled grade 1 min. | 0.183 | mm | |

| Enamelled grade 1 max. | 0.194 | mm | |

| Enamelled grade 2 min. | 0.195 | mm | |

| Enamelled grade 2 max. | 0.205 | mm | |

| Conductor nominal Ø | 0.180 | mm | |

| Conductor cross section | 0.025 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.069 | kg/km | |

| Copper | Resistance min. | 0.6444 | Ω/m |

| Resistance max. | 0.7007 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.227 | kg/km | |

| Ø | Conductor min. | 0.177 | mm |

| Conductor max. | 0.183 | mm | |

| Enamelled grade 1 min. | 0.193 | mm | |

| Enamelled grade 1 max. | 0.204 | mm | |

| Enamelled grade 2 min. | 0.205 | mm | |

| Enamelled grade 2 max. | 0.217 | mm | |

| Conductor nominal Ø | 0.190 | mm | |

| Conductor cross section | 0.028 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.077 | kg/km | |

| Copper | Resistance min. | 0.5794 | Ω/m |

| Resistance max. | 0.6278 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.253 | kg/km | |

| Ø | Conductor min. | 0.187 | mm |

| Conductor max. | 0.193 | mm | |

| Enamelled grade 1 min. | 0.204 | mm | |

| Enamelled grade 1 max. | 0.216 | mm | |

| Enamelled grade 2 min. | 0.217 | mm | |

| Enamelled grade 2 max. | 0.228 | mm | |

| Conductor nominal Ø | 0.200 | mm | |

| Conductor cross section | 0.031 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.085 | kg/km | |

| Copper | Resistance min. | 0.5237 | Ω/m |

| Resistance max. | 0.5657 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.280 | kg/km | |

| Ø | Conductor min. | 0.197 | mm |

| Conductor max. | 0.203 | mm | |

| Enamelled grade 1 min. | 0.214 | mm | |

| Enamelled grade 1 max. | 0.226 | mm | |

| Enamelled grade 2 min. | 0.227 | mm | |

| Enamelled grade 2 max. | 0.239 | mm | |

| Conductor nominal Ø | 0.212 | mm | |

| Conductor cross section | 0.035 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.095 | kg/km | |

| Copper | Resistance min. | 0.4669 | Ω/m |

| Resistance max. | 0.5026 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.315 | kg/km | |

| Ø | Conductor min. | 0.209 | mm |

| Conductor max. | 0.215 | mm | |

| Enamelled grade 1 min. | 0.227 | mm | |

| Enamelled grade 1 max. | 0.240 | mm | |

| Enamelled grade 2 min. | 0.241 | mm | |

| Enamelled grade 2 max. | 0.254 | mm | |

| Conductor nominal Ø | 0.224 | mm | |

| Conductor cross section | 0.039 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.106 | kg/km | |

| Copper | Resistance min. | 0.4188 | Ω/m |

| Resistance max. | 0.4495 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.352 | kg/km | |

| Ø | Conductor min. | 0.221 | mm |

| Conductor max. | 0.227 | mm | |

| Enamelled grade 1 min. | 0.239 | mm | |

| Enamelled grade 1 max. | 0.252 | mm | |

| Enamelled grade 2 min. | 0.253 | mm | |

| Enamelled grade 2 max. | 0.266 | mm | |

| Conductor nominal Ø | 0.236 | mm | |

| Conductor cross section | 0.044 | mm² | |

| Aluminium | Resistance min. | - | Ω/m |

| Resistance max. | - | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.118 | kg/km | |

| Copper | Resistance min. | 0.3747 | Ω/m |

| Resistance max. | 0.4079 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.390 | kg/km | |

| Ø | Conductor min. | 0.232 | mm |

| Conductor max. | 0.240 | mm | |

| Enamelled grade 1 min. | 0.253 | mm | |

| Enamelled grade 1 max. | 0.267 | mm | |

| Enamelled grade 2 min. | 0.268 | mm | |

| Enamelled grade 2 max. | 0.283 | mm | |

| Conductor nominal Ø | 0.250 | mm | |

| Conductor cross section | 0.049 | mm² | |

| Aluminium | Resistance min. | 0.5452 | Ω/m |

| Resistance max. | 0.5927 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.133 | kg/km | |

| Copper | Resistance min. | 0.3345 | Ω/m |

| Resistance max. | 0.3628 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.438 | kg/km | |

| Ø | Conductor min. | 0.246 | mm |

| Conductor max. | 0.254 | mm | |

| Enamelled grade 1 min. | 0.267 | mm | |

| Enamelled grade 1 max. | 0.281 | mm | |

| Enamelled grade 2 min. | 0.282 | mm | |

| Enamelled grade 2 max. | 0.297 | mm | |

| Conductor nominal Ø | 0.265 | mm | |

| Conductor cross section | 0.055 | mm² | |

| Aluminium | Resistance min. | 0.4861 | Ω/m |

| Resistance max. | 0.5265 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.149 | kg/km | |

| Copper | Resistance min. | 0.2982 | Ω/m |

| Resistance max. | 0.3223 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.492 | kg/km | |

| Ø | Conductor min. | 0.261 | mm |

| Conductor max. | 0.269 | mm | |

| Enamelled grade 1 min. | 0.283 | mm | |

| Enamelled grade 1 max. | 0.297 | mm | |

| Enamelled grade 2 min. | 0.298 | mm | |

| Enamelled grade 2 max. | 0.314 | mm | |

| Conductor nominal Ø | 0.280 | mm | |

| Conductor cross section | 0.062 | mm² | |

| Aluminium | Resistance min. | 0.4361 | Ω/m |

| Resistance max. | 0.4708 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.166 | kg/km | |

| Copper | Resistance min. | 0.2676 | Ω/m |

| Resistance max. | 0.2882 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.549 | kg/km | |

| Ø | Conductor min. | 0.276 | mm |

| Conductor max. | 0.284 | mm | |

| Enamelled grade 1 min. | 0.298 | mm | |

| Enamelled grade 1 max. | 0.312 | mm | |

| Enamelled grade 2 min. | 0.313 | mm | |

| Enamelled grade 2 max. | 0.329 | mm | |

| Conductor nominal Ø | 0.300 | mm | |

| Conductor cross section | 0.071 | mm² | |

| Aluminium | Resistance min. | 0.3806 | Ω/m |

| Resistance max. | 0.4094 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.191 | kg/km | |

| Copper | Resistance min. | 0.2335 | Ω/m |

| Resistance max. | 0.2506 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.631 | kg/km | |

| Ø | Conductor min. | 0.296 | mm |

| Conductor max. | 0.304 | mm | |

| Enamelled grade 1 min. | 0.319 | mm | |

| Enamelled grade 1 max. | 0.334 | mm | |

| Enamelled grade 2 min. | 0.335 | mm | |

| Enamelled grade 2 max. | 0.352 | mm | |

| Conductor nominal Ø | 0.315 | mm | |

| Conductor cross section | 0.078 | mm² | |

| Aluminium | Resistance min. | 0.3456 | Ω/m |

| Resistance max. | 0.3708 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.210 | kg/km | |

| Copper | Resistance min. | 0.2121 | Ω/m |

| Resistance max. | 0.2270 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.695 | kg/km | |

| Ø | Conductor min. | 0.311 | mm |

| Conductor max. | 0.319 | mm | |

| Enamelled grade 1 min. | 0.334 | mm | |

| Enamelled grade 1 max. | 0.349 | mm | |

| Enamelled grade 2 min. | 0.350 | mm | |

| Enamelled grade 2 max. | 0.367 | mm | |

| Conductor nominal Ø | 0.335 | mm | |

| Conductor cross section | 0.088 | mm² | |

| Aluminium | Resistance min. | 0.3061 | Ω/m |

| Resistance max. | 0.3274 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.238 | kg/km | |

| Copper | Resistance min. | 0.1878 | Ω/m |

| Resistance max. | 0.2004 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.786 | kg/km | |

| Ø | Conductor min. | 0.331 | mm |

| Conductor max. | 0.339 | mm | |

| Enamelled grade 1 min. | 0.355 | mm | |

| Enamelled grade 1 max. | 0.372 | mm | |

| Enamelled grade 2 min. | 0.373 | mm | |

| Enamelled grade 2 max. | 0.391 | mm | |

| Conductor nominal Ø | 0.355 | mm | |

| Conductor cross section | 0.099 | mm² | |

| Aluminium | Resistance min. | 0.2729 | Ω/m |

| Resistance max. | 0.2911 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.267 | kg/km | |

| Copper | Resistance min. | 0.1674 | Ω/m |

| Resistance max. | 0.1782 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.883 | kg/km | |

| Ø | Conductor min. | 0.351 | mm |

| Conductor max. | 0.359 | mm | |

| Enamelled grade 1 min. | 0.375 | mm | |

| Enamelled grade 1 max. | 0.392 | mm | |

| Enamelled grade 2 min. | 0.393 | mm | |

| Enamelled grade 2 max. | 0.411 | mm | |

| Conductor nominal Ø | 0.375 | mm | |

| Conductor cross section | 0.110 | mm² | |

| Aluminium | Resistance min. | 0.2436 | Ω/m |

| Resistance max. | 0.2620 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.298 | kg/km | |

| Copper | Resistance min. | 0.1495 | Ω/m |

| Resistance max. | 0.1604 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 0.985 | kg/km | |

| Ø | Conductor min. | 0.370 | mm |

| Conductor max. | 0.380 | mm | |

| Enamelled grade 1 min. | 0.396 | mm | |

| Enamelled grade 1 max. | 0.414 | mm | |

| Enamelled grade 2 min. | 0.415 | mm | |

| Enamelled grade 2 max. | 0.434 | mm | |

| Conductor nominal Ø | 0.400 | mm | |

| Conductor cross section | 0.126 | mm² | |

| Aluminium | Resistance min. | 0.2144 | Ω/m |

| Resistance max. | 0.2299 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.339 | kg/km | |

| Copper | Resistance min. | 0.1316 | Ω/m |

| Resistance max. | 0.1407 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 1.121 | kg/km | |

| Ø | Conductor min. | 0.395 | mm |

| Conductor max. | 0.405 | mm | |

| Enamelled grade 1 min. | 0.421 | mm | |

| Enamelled grade 1 max. | 0.439 | mm | |

| Enamelled grade 2 min. | 0.440 | mm | |

| Enamelled grade 2 max. | 0.459 | mm | |

| Conductor nominal Ø | 0.425 | mm | |

| Conductor cross section | 0.142 | mm² | |

| Aluminium | Resistance min. | 0.1902 | Ω/m |

| Resistance max. | 0.2033 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.383 | kg/km | |

| Copper | Resistance min. | 0.1167 | Ω/m |

| Resistance max. | 0.1245 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 1.265 | kg/km | |

| Ø | Conductor min. | 0.420 | mm |

| Conductor max. | 0.430 | mm | |

| Enamelled grade 1 min. | 0.447 | mm | |

| Enamelled grade 1 max. | 0.466 | mm | |

| Enamelled grade 2 min. | 0.467 | mm | |

| Enamelled grade 2 max. | 0.488 | mm | |

| Conductor nominal Ø | 0.450 | mm | |

| Conductor cross section | 0.159 | mm² | |

| Aluminium | Resistance min. | 0.1699 | Ω/m |

| Resistance max. | 0.1811 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.429 | kg/km | |

| Copper | Resistance min. | 0.1042 | Ω/m |

| Resistance max. | 0.1109 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 1.419 | kg/km | |

| Ø | Conductor min. | 0.445 | mm |

| Conductor max. | 0.455 | mm | |

| Enamelled grade 1 min. | 0.472 | mm | |

| Enamelled grade 1 max. | 0.491 | mm | |

| Enamelled grade 2 min. | 0.492 | mm | |

| Enamelled grade 2 max. | 0.513 | mm | |

| Conductor nominal Ø | 0.475 | mm | |

| Conductor cross section | 0.177 | mm² | |

| Aluminium | Resistance min. | 0.1527 | Ω/m |

| Resistance max. | 0.1624 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.478 | kg/km | |

| Copper | Resistance min. | 0.0937 | Ω/m |

| Resistance max. | 0.0994 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 1.581 | kg/km | |

| Ø | Conductor min. | 0.470 | mm |

| Conductor max. | 0.480 | mm | |

| Enamelled grade 1 min. | 0.499 | mm | |

| Enamelled grade 1 max. | 0.519 | mm | |

| Enamelled grade 2 min. | 0.520 | mm | |

| Enamelled grade 2 max. | 0.541 | mm | |

| Conductor nominal Ø | 0.500 | mm | |

| Conductor cross section | 0.196 | mm² | |

| Aluminium | Resistance min. | 0.1379 | Ω/m |

| Resistance max. | 0.1464 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.530 | kg/km | |

| Copper | Resistance min. | 0.0846 | Ω/m |

| Resistance max. | 0.0896 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 1.751 | kg/km | |

| Ø | Conductor min. | 0.495 | mm |

| Conductor max. | 0.505 | mm | |

| Enamelled grade 1 min. | 0.524 | mm | |

| Enamelled grade 1 max. | 0.544 | mm | |

| Enamelled grade 2 min. | 0.545 | mm | |

| Enamelled grade 2 max. | 0.566 | mm | |

| Conductor nominal Ø | 0.530 | mm | |

| Conductor cross section | 0.221 | mm² | |

| Aluminium | Resistance min. | 0.1224 | Ω/m |

| Resistance max. | 0.1306 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.596 | kg/km | |

| Copper | Resistance min. | 0.0751 | Ω/m |

| Resistance max. | 0.0800 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 1.968 | kg/km | |

| Ø | Conductor min. | 0.524 | mm |

| Conductor max. | 0.536 | mm | |

| Enamelled grade 1 min. | 0.555 | mm | |

| Enamelled grade 1 max. | 0.576 | mm | |

| Enamelled grade 2 min. | 0.577 | mm | |

| Enamelled grade 2 max. | 0.600 | mm | |

| Conductor nominal Ø | 0.560 | mm | |

| Conductor cross section | 0.246 | mm² | |

| Aluminium | Resistance min. | 0.1098 | Ω/m |

| Resistance max. | 0.1169 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.665 | kg/km | |

| Copper | Resistance min. | 0.0674 | Ω/m |

| Resistance max. | 0.0715 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 2.197 | kg/km | |

| Ø | Conductor min. | 0.554 | mm |

| Conductor max. | 0.566 | mm | |

| Enamelled grade 1 min. | 0.585 | mm | |

| Enamelled grade 1 max. | 0.606 | mm | |

| Enamelled grade 2 min. | 0.607 | mm | |

| Enamelled grade 2 max. | 0.630 | mm | |

| Conductor nominal Ø | 0.600 | mm | |

| Conductor cross section | 0.283 | mm² | |

| Aluminium | Resistance min. | 0.0958 | Ω/m |

| Resistance max. | 0.1017 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.763 | kg/km | |

| Copper | Resistance min. | 0.0588 | Ω/m |

| Resistance max. | 0.0622 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 2.522 | kg/km | |

| Ø | Conductor min. | 0.594 | mm |

| Conductor max. | 0.606 | mm | |

| Enamelled grade 1 min. | 0.627 | mm | |

| Enamelled grade 1 max. | 0.649 | mm | |

| Enamelled grade 2 min. | 0.650 | mm | |

| Enamelled grade 2 max. | 0.674 | mm | |

| Conductor nominal Ø | 0.630 | mm | |

| Conductor cross section | 0.312 | mm² | |

| Aluminium | Resistance min. | 0.0870 | Ω/m |

| Resistance max. | 0.0921 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.842 | kg/km | |

| Copper | Resistance min. | 0.0534 | Ω/m |

| Resistance max. | 0.0564 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 2.781 | kg/km | |

| Ø | Conductor min. | 0.624 | mm |

| Conductor max. | 0.636 | mm | |

| Enamelled grade 1 min. | 0.657 | mm | |

| Enamelled grade 1 max. | 0.679 | mm | |

| Enamelled grade 2 min. | 0.680 | mm | |

| Enamelled grade 2 max. | 0.704 | mm | |

| Conductor nominal Ø | 0.670 | mm | |

| Conductor cross section | 0.353 | mm² | |

| Aluminium | Resistance min. | 0.0767 | Ω/m |

| Resistance max. | 0.0816 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 0.952 | kg/km | |

| Copper | Resistance min. | 0.0471 | Ω/m |

| Resistance max. | 0.0499 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 3.145 | kg/km | |

| Ø | Conductor min. | 0.663 | mm |

| Conductor max. | 0.677 | mm | |

| Enamelled grade 1 min. | 0.698 | mm | |

| Enamelled grade 1 max. | 0.722 | mm | |

| Enamelled grade 2 min. | 0.723 | mm | |

| Enamelled grade 2 max. | 0.749 | mm | |

| Conductor nominal Ø | 0.710 | mm | |

| Conductor cross section | 0.396 | mm² | |

| Aluminium | Resistance min. | 0.0684 | Ω/m |

| Resistance max. | 0.0726 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 1.069 | kg/km | |

| Copper | Resistance min. | 0.0420 | Ω/m |

| Resistance max. | 0.0444 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 3.532 | kg/km | |

| Ø | Conductor min. | 0.703 | mm |

| Conductor max. | 0.717 | mm | |

| Enamelled grade 1 min. | 0.738 | mm | |

| Enamelled grade 1 max. | 0.762 | mm | |

| Enamelled grade 2 min. | 0.763 | mm | |

| Enamelled grade 2 max. | 0.789 | mm | |

| Conductor nominal Ø | 0.750 | mm | |

| Conductor cross section | 0.442 | mm² | |

| Aluminium | Resistance min. | 0.0612 | Ω/m |

| Resistance max. | 0.0651 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 1.193 | kg/km | |

| Copper | Resistance min. | 0.0376 | Ω/m |

| Resistance max. | 0.0399 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 3.941 | kg/km | |

| Ø | Conductor min. | 0.742 | mm |

| Conductor max. | 0.758 | mm | |

| Enamelled grade 1 min. | 0.780 | mm | |

| Enamelled grade 1 max. | 0.805 | mm | |

| Enamelled grade 2 min. | 0.806 | mm | |

| Enamelled grade 2 max. | 0.834 | mm | |

| Conductor nominal Ø | 0.800 | mm | |

| Conductor cross section | 0.503 | mm² | |

| Aluminium | Resistance min. | 0.0539 | Ω/m |

| Resistance max. | 0.0572 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 1.357 | kg/km | |

| Copper | Resistance min. | 0.0331 | Ω/m |

| Resistance max. | 0.0350 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 4.484 | kg/km | |

| Ø | Conductor min. | 0.792 | mm |

| Conductor max. | 0.808 | mm | |

| Enamelled grade 1 min. | 0.830 | mm | |

| Enamelled grade 1 max. | 0.855 | mm | |

| Enamelled grade 2 min. | 0.856 | mm | |

| Enamelled grade 2 max. | 0.884 | mm | |

| Conductor nominal Ø | 0.850 | mm | |

| Conductor cross section | 0.567 | mm² | |

| Aluminium | Resistance min. | 0.0477 | Ω/m |

| Resistance max. | 0.0507 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 1.532 | kg/km | |

| Copper | Resistance min. | 0.0292 | Ω/m |

| Resistance max. | 0.0310 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 5.062 | kg/km | |

| Ø | Conductor min. | 0.841 | mm |

| Conductor max. | 0.859 | mm | |

| Enamelled grade 1 min. | 0.882 | mm | |

| Enamelled grade 1 max. | 0.909 | mm | |

| Enamelled grade 2 min. | 0.910 | mm | |

| Enamelled grade 2 max. | 0.939 | mm | |

| Conductor nominal Ø | 0.900 | mm | |

| Conductor cross section | 0.636 | mm² | |

| Aluminium | Resistance min. | 0.0426 | Ω/m |

| Resistance max. | 0.0452 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 1.718 | kg/km | |

| Copper | Resistance min. | 0.0261 | Ω/m |

| Resistance max. | 0.0277 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 5.675 | kg/km | |

| Ø | Conductor min. | 0.891 | mm |

| Conductor max. | 0.909 | mm | |

| Enamelled grade 1 min. | 0.932 | mm | |

| Enamelled grade 1 max. | 0.959 | mm | |

| Enamelled grade 2 min. | 0.960 | mm | |

| Enamelled grade 2 max. | 0.989 | mm | |

| Conductor nominal Ø | 0.950 | mm | |

| Conductor cross section | 0.709 | mm² | |

| Aluminium | Resistance min. | 0.0382 | Ω/m |

| Resistance max. | 0.0406 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 1.914 | kg/km | |

| Copper | Resistance min. | 0.0234 | Ω/m |

| Resistance max. | 0.0248 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 6.323 | kg/km | |

| Ø | Conductor min. | 0.940 | mm |

| Conductor max. | 0.960 | mm | |

| Enamelled grade 1 min. | 0.984 | mm | |

| Enamelled grade 1 max. | 1.012 | mm | |

| Enamelled grade 2 min. | 1.013 | mm | |

| Enamelled grade 2 max. | 1.044 | mm | |

| Conductor nominal Ø | 1.000 | mm | |

| Conductor cross section | 0.785 | mm² | |

| Aluminium | Resistance min. | 0.0345 | Ω/m |

| Resistance max. | 0.0366 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 2.121 | kg/km | |

| Copper | Resistance min. | 0.0212 | Ω/m |

| Resistance max. | 0.0224 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 7.006 | kg/km | |

| Ø | Conductor min. | 0.990 | mm |

| Conductor max. | 1.010 | mm | |

| Enamelled grade 1 min. | 1.034 | mm | |

| Enamelled grade 1 max. | 1.062 | mm | |

| Enamelled grade 2 min. | 1.063 | mm | |

| Enamelled grade 2 max. | 1.094 | mm | |

| Conductor nominal Ø | 1.060 | mm | |

| Conductor cross section | 0.882 | mm² | |

| Aluminium | Resistance min. | 0.0307 | Ω/m |

| Resistance max. | 0.0326 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 2.383 | kg/km | |

| Copper | Resistance min. | 0.0188 | Ω/m |

| Resistance max. | 0.0199 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 7.872 | kg/km | |

| Ø | Conductor min. | 1.049 | mm |

| Conductor max. | 1.071 | mm | |

| Enamelled grade 1 min. | 1.094 | mm | |

| Enamelled grade 1 max. | 1.124 | mm | |

| Enamelled grade 2 min. | 1.125 | mm | |

| Enamelled grade 2 max. | 1.157 | mm | |

| Conductor nominal Ø | 1.120 | mm | |

| Conductor cross section | 0.985 | mm² | |

| Aluminium | Resistance min. | 0.0275 | Ω/m |

| Resistance max. | 0.0292 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 2.660 | kg/km | |

| Copper | Resistance min. | 0.0169 | Ω/m |

| Resistance max. | 0.0178 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 8.788 | kg/km | |

| Ø | Conductor min. | 1.109 | mm |

| Conductor max. | 1.131 | mm | |

| Enamelled grade 1 min. | 1.154 | mm | |

| Enamelled grade 1 max. | 1.184 | mm | |

| Enamelled grade 2 min. | 1.185 | mm | |

| Enamelled grade 2 max. | 1.217 | mm | |

| Conductor nominal Ø | 1.180 | mm | |

| Conductor cross section | 1.094 | mm² | |

| Aluminium | Resistance min. | 0.0248 | Ω/m |

| Resistance max. | 0.0263 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 2.953 | kg/km | |

| Copper | Resistance min. | 0.0152 | Ω/m |

| Resistance max. | 0.0161 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 9.755 | kg/km | |

| Ø | Conductor min. | 1.168 | mm |

| Conductor max. | 1.192 | mm | |

| Enamelled grade 1 min. | 1.215 | mm | |

| Enamelled grade 1 max. | 1.246 | mm | |

| Enamelled grade 2 min. | 1.247 | mm | |

| Enamelled grade 2 max. | 1.279 | mm | |

| Conductor nominal Ø | 1.250 | mm | |

| Conductor cross section | 1.227 | mm² | |

| Aluminium | Resistance min. | 0.0220 | Ω/m |

| Resistance max. | 0.0234 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 3.313 | kg/km | |

| Copper | Resistance min. | 0.0135 | Ω/m |

| Resistance max. | 0.0143 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 10.946 | kg/km | |

| Ø | Conductor min. | 1.237 | mm |

| Conductor max. | 1.263 | mm | |

| Enamelled grade 1 min. | 1.285 | mm | |

| Enamelled grade 1 max. | 1.316 | mm | |

| Enamelled grade 2 min. | 1.317 | mm | |

| Enamelled grade 2 max. | 1.349 | mm | |

| Conductor nominal Ø | 1.320 | mm | |

| Conductor cross section | 1.368 | mm² | |

| Aluminium | Resistance min. | 0.0198 | Ω/m |

| Resistance max. | 0.0210 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 3.695 | kg/km | |

| Copper | Resistance min. | 0.0121 | Ω/m |

| Resistance max. | 0.0129 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 12.207 | kg/km | |

| Ø | Conductor min. | 1.307 | mm |

| Conductor max. | 1.333 | mm | |

| Enamelled grade 1 min. | 1.356 | mm | |

| Enamelled grade 1 max. | 1.388 | mm | |

| Enamelled grade 2 min. | 1.389 | mm | |

| Enamelled grade 2 max. | 1.422 | mm | |

| Conductor nominal Ø | 1.400 | mm | |

| Conductor cross section | 1.539 | mm² | |

| Aluminium | Resistance min. | 0.0176 | Ω/m |

| Resistance max. | 0.0187 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 4.156 | kg/km | |

| Copper | Resistance min. | 0.0108 | Ω/m |

| Resistance max. | 0.0114 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 13.731 | kg/km | |

| Ø | Conductor min. | 1.386 | mm |

| Conductor max. | 1.414 | mm | |

| Enamelled grade 1 min. | 1.436 | mm | |

| Enamelled grade 1 max. | 1.468 | mm | |

| Enamelled grade 2 min. | 1.469 | mm | |

| Enamelled grade 2 max. | 1.502 | mm | |

| Conductor nominal Ø | 1.500 | mm | |

| Conductor cross section | 1.767 | mm² | |

| Aluminium | Resistance min. | 0.0153 | Ω/m |

| Resistance max. | 0.0163 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 4.771 | kg/km | |

| Copper | Resistance min. | 0.0094 | Ω/m |

| Resistance max. | 0.0100 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 15.763 | kg/km | |

| Ø | Conductor min. | 1.485 | mm |

| Conductor max. | 1.515 | mm | |

| Enamelled grade 1 min. | 1.538 | mm | |

| Enamelled grade 1 max. | 1.570 | mm | |

| Enamelled grade 2 min. | 1.571 | mm | |

| Enamelled grade 2 max. | 1.606 | mm | |

| Conductor nominal Ø | 1.600 | mm | |

| Conductor cross section | 2.011 | mm² | |

| Aluminium | Resistance min. | 0.0135 | Ω/m |

| Resistance max. | 0.0143 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 5.429 | kg/km | |

| Copper | Resistance min. | 0.0083 | Ω/m |

| Resistance max. | 0.0087 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 17.935 | kg/km | |

| Ø | Conductor min. | 1.584 | mm |

| Conductor max. | 1.616 | mm | |

| Enamelled grade 1 min. | 1.638 | mm | |

| Enamelled grade 1 max. | 1.670 | mm | |

| Enamelled grade 2 min. | 1.671 | mm | |

| Enamelled grade 2 max. | 1.706 | mm | |

| Conductor nominal Ø | 1.700 | mm | |

| Conductor cross section | 2.270 | mm² | |

| Aluminium | Resistance min. | 0.0119 | Ω/m |

| Resistance max. | 0.0127 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 6.128 | kg/km | |

| Copper | Resistance min. | 0.0073 | Ω/m |

| Resistance max. | 0.0078 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 20.247 | kg/km | |

| Ø | Conductor min. | 1.683 | mm |

| Conductor max. | 1.717 | mm | |

| Enamelled grade 1 min. | 1.739 | mm | |

| Enamelled grade 1 max. | 1.772 | mm | |

| Enamelled grade 2 min. | 1.773 | mm | |

| Enamelled grade 2 max. | 1.809 | mm | |

| Conductor nominal Ø | 1.800 | mm | |

| Conductor cross section | 2.545 | mm² | |

| Aluminium | Resistance min. | 0.0106 | Ω/m |

| Resistance max. | 0.0113 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 6.871 | kg/km | |

| Copper | Resistance min. | 0.0065 | Ω/m |

| Resistance max. | 0.0069 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 22.699 | kg/km | |

| Ø | Conductor min. | 1.782 | mm |

| Conductor max. | 1.818 | mm | |

| Enamelled grade 1 min. | 1.839 | mm | |

| Enamelled grade 1 max. | 1.872 | mm | |

| Enamelled grade 2 min. | 1.873 | mm | |

| Enamelled grade 2 max. | 1.909 | mm | |

| Conductor nominal Ø | 1.900 | mm | |

| Conductor cross section | 2.835 | mm² | |

| Aluminium | Resistance min. | 0.0096 | Ω/m |

| Resistance max. | 0.0101 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 7.655 | kg/km | |

| Copper | Resistance min. | 0.0059 | Ω/m |

| Resistance max. | 0.0062 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 25.291 | kg/km | |

| Ø | Conductor min. | 1.881 | mm |

| Conductor max. | 1.919 | mm | |

| Enamelled grade 1 min. | 1.940 | mm | |

| Enamelled grade 1 max. | 1.974 | mm | |

| Enamelled grade 2 min. | 1.975 | mm | |

| Enamelled grade 2 max. | 2.012 | mm | |

| Conductor nominal Ø | 2.000 | mm | |

| Conductor cross section | 3.142 | mm² | |

| Aluminium | Resistance min. | 0.0086 | Ω/m |

| Resistance max. | 0.0091 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 8.482 | kg/km | |

| Copper | Resistance min. | 0.0053 | Ω/m |

| Resistance max. | 0.0056 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 28.023 | kg/km | |

| Ø | Conductor min. | 1.980 | mm |

| Conductor max. | 2.020 | mm | |

| Enamelled grade 1 min. | 2.040 | mm | |

| Enamelled grade 1 max. | 2.074 | mm | |

| Enamelled grade 2 min. | 2.075 | mm | |

| Enamelled grade 2 max. | 2.112 | mm | |

| Conductor nominal Ø | 2.120 | mm | |

| Conductor cross section | 3.530 | mm² | |

| Aluminium | Resistance min. | 0.0077 | Ω/m |

| Resistance max. | 0.0081 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 9.531 | kg/km | |

| Copper | Resistance min. | 0.0047 | Ω/m |

| Resistance max. | 0.0050 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 31.487 | kg/km | |

| Ø | Conductor min. | 2.099 | mm |

| Conductor max. | 2.141 | mm | |

| Enamelled grade 1 min. | 2.161 | mm | |

| Enamelled grade 1 max. | 2.196 | mm | |

| Enamelled grade 2 min. | 2.197 | mm | |

| Enamelled grade 2 max. | 2.235 | mm | |

| Conductor nominal Ø | 2.240 | mm | |

| Conductor cross section | 3.941 | mm² | |

| Aluminium | Resistance min. | 0.0069 | Ω/m |

| Resistance max. | 0.0073 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 10.640 | kg/km | |

| Copper | Resistance min. | 0.0042 | Ω/m |

| Resistance max. | 0.0045 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 35.152 | kg/km | |

| Ø | Conductor min. | 2.218 | mm |

| Conductor max. | 2.262 | mm | |

| Enamelled grade 1 min. | 2.281 | mm | |

| Enamelled grade 1 max. | 2.316 | mm | |

| Enamelled grade 2 min. | 2.317 | mm | |

| Enamelled grade 2 max. | 2.355 | mm | |

| Conductor nominal Ø | 2.360 | mm | |

| Conductor cross section | 4.374 | mm² | |

| Aluminium | Resistance min. | 0.0062 | Ω/m |

| Resistance max. | 0.0066 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 11.811 | kg/km | |

| Copper | Resistance min. | 0.0038 | Ω/m |

| Resistance max. | 0.0040 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 39.019 | kg/km | |

| Ø | Conductor min. | 2.336 | mm |

| Conductor max. | 2.384 | mm | |

| Enamelled grade 1 min. | 2.402 | mm | |

| Enamelled grade 1 max. | 2.438 | mm | |

| Enamelled grade 2 min. | 2.439 | mm | |

| Enamelled grade 2 max. | 2.478 | mm | |

| Conductor nominal Ø | 2.500 | mm | |

| Conductor cross section | 4.909 | mm² | |

| Aluminium | Resistance min. | 0.0055 | Ω/m |

| Resistance max. | 0.0059 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 13.254 | kg/km | |

| Copper | Resistance min. | 0.0034 | Ω/m |

| Resistance max. | 0.0036 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 43.786 | kg/km | |

| Ø | Conductor min. | 2.475 | mm |

| Conductor max. | 2.525 | mm | |

| Enamelled grade 1 min. | 2.542 | mm | |

| Enamelled grade 1 max. | 2.578 | mm | |

| Enamelled grade 2 min. | 2.579 | mm | |

| Enamelled grade 2 max. | 2.618 | mm | |

| Conductor nominal Ø | 2.650 | mm | |

| Conductor cross section | 5.515 | mm² | |

| Aluminium | Resistance min. | 0.0049 | Ω/m |

| Resistance max. | 0.0052 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 14.892 | kg/km | |

| Copper | Resistance min. | 0.0030 | Ω/m |

| Resistance max. | 0.0032 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 49.198 | kg/km | |

| Ø | Conductor min. | 2.623 | mm |

| Conductor max. | 2.677 | mm | |

| Enamelled grade 1 min. | 2.693 | mm | |

| Enamelled grade 1 max. | 2.730 | mm | |

| Enamelled grade 2 min. | 2.731 | mm | |

| Enamelled grade 2 max. | 2.772 | mm | |

| Conductor nominal Ø | 2.800 | mm | |

| Conductor cross section | 6.158 | mm² | |

| Aluminium | Resistance min. | 0.0044 | Ω/m |

| Resistance max. | 0.0047 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 16.625 | kg/km | |

| Copper | Resistance min. | 0.0027 | Ω/m |

| Resistance max. | 0.0029 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 54.925 | kg/km | |

| Ø | Conductor min. | 2.772 | mm |

| Conductor max. | 2.828 | mm | |

| Enamelled grade 1 min. | 2.843 | mm | |

| Enamelled grade 1 max. | 2.880 | mm | |

| Enamelled grade 2 min. | 2.881 | mm | |

| Enamelled grade 2 max. | 2.922 | mm | |

| Conductor nominal Ø | 3.000 | mm | |

| Conductor cross section | 7.069 | mm² | |

| Aluminium | Resistance min. | 0.0038 | Ω/m |

| Resistance max. | 0.0041 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 19.085 | kg/km | |

| Copper | Resistance min. | 0.0024 | Ω/m |

| Resistance max. | 0.0025 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 63.052 | kg/km | |

| Ø | Conductor min. | 2.970 | mm |

| Conductor max. | 3.030 | mm | |

| Enamelled grade 1 min. | 3.045 | mm | |

| Enamelled grade 1 max. | 3.083 | mm | |

| Enamelled grade 2 min. | 3.084 | mm | |

| Enamelled grade 2 max. | 3.126 | mm | |

| Conductor nominal Ø | 3.150 | mm | |

| Conductor cross section | 7.793 | mm² | |

| Aluminium | Resistance min. | 0.0035 | Ω/m |

| Resistance max. | 0.0037 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 21.041 | kg/km | |

| Copper | Resistance min. | 0.0021 | Ω/m |

| Resistance max. | 0.0023 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 69.515 | kg/km | |

| Ø | Conductor min. | 3.118 | mm |

| Conductor max. | 3.182 | mm | |

| Enamelled grade 1 min. | 3.195 | mm | |

| Enamelled grade 1 max. | 3.233 | mm | |

| Enamelled grade 2 min. | 3.234 | mm | |

| Enamelled grade 2 max. | 3.276 | mm | |

| Conductor nominal Ø | 3.350 | mm | |

| Conductor cross section | 8.814 | mm² | |

| Aluminium | Resistance min. | 0.0031 | Ω/m |

| Resistance max. | 0.0033 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 23.798 | kg/km | |

| Copper | Resistance min. | 0.0019 | Ω/m |

| Resistance max. | 0.0020 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 78.622 | kg/km | |

| Ø | Conductor min. | 3.316 | mm |

| Conductor max. | 3.384 | mm | |

| Enamelled grade 1 min. | 3.396 | mm | |

| Enamelled grade 1 max. | 3.435 | mm | |

| Enamelled grade 2 min. | 3.436 | mm | |

| Enamelled grade 2 max. | 3.479 | mm | |

| Conductor nominal Ø | 3.550 | mm | |

| Conductor cross section | 9.898 | mm² | |

| Aluminium | Resistance min. | 0.0027 | Ω/m |

| Resistance max. | 0.0029 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 26.725 | kg/km | |

| Copper | Resistance min. | 0.0017 | Ω/m |

| Resistance max. | 0.0018 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 88.290 | kg/km | |

| Ø | Conductor min. | 3.514 | mm |

| Conductor max. | 3.586 | mm | |

| Enamelled grade 1 min. | 3.596 | mm | |

| Enamelled grade 1 max. | 3.635 | mm | |

| Enamelled grade 2 min. | 3.636 | mm | |

| Enamelled grade 2 max. | 3.679 | mm | |

| Conductor nominal Ø | 3.750 | mm | |

| Conductor cross section | 11.045 | mm² | |

| Aluminium | Resistance min. | 0.0025 | Ω/m |

| Resistance max. | 0.0026 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 29.821 | kg/km | |

| Copper | Resistance min. | 0.0015 | Ω/m |

| Resistance max. | 0.0016 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 98.518 | kg/km | |

| Ø | Conductor min. | 3.712 | mm |

| Conductor max. | 3.788 | mm | |

| Enamelled grade 1 min. | 3.797 | mm | |

| Enamelled grade 1 max. | 3.838 | mm | |

| Enamelled grade 2 min. | 3.839 | mm | |

| Enamelled grade 2 max. | 3.883 | mm | |

| Conductor nominal Ø | 4.000 | mm | |

| Conductor cross section | 12.566 | mm² | |

| Aluminium | Resistance min. | 0.0022 | Ω/m |

| Resistance max. | 0.0023 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 33.929 | kg/km | |

| Copper | Resistance min. | 0.0013 | Ω/m |

| Resistance max. | 0.0014 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 112.092 | kg/km | |

| Ø | Conductor min. | 3.960 | mm |

| Conductor max. | 4.040 | mm | |

| Enamelled grade 1 min. | 4.047 | mm | |

| Enamelled grade 1 max. | 4.088 | mm | |

| Enamelled grade 2 min. | 4.089 | mm | |

| Enamelled grade 2 max. | 4.133 | mm | |

| Conductor nominal Ø | 4.250 | mm | |

| Conductor cross section | 14.186 | mm² | |

| Aluminium | Resistance min. | 0.0019 | Ω/m |

| Resistance max. | 0.0020 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 38.303 | kg/km | |

| Copper | Resistance min. | 0.0012 | Ω/m |

| Resistance max. | 0.0012 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 126.541 | kg/km | |

| Ø | Conductor min. | 4.207 | mm |

| Conductor max. | 4.293 | mm | |

| Enamelled grade 1 min. | 4.299 | mm | |

| Enamelled grade 1 max. | 4.341 | mm | |

| Enamelled grade 2 min. | 4.342 | mm | |

| Enamelled grade 2 max. | 4.387 | mm | |

| Conductor nominal Ø | 4.500 | mm | |

| Conductor cross section | 15.904 | mm² | |

| Aluminium | Resistance min. | 0.0017 | Ω/m |

| Resistance max. | 0.0018 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 42.942 | kg/km | |

| Copper | Resistance min. | 0.0010 | Ω/m |

| Resistance max. | 0.0011 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 141.866 | kg/km | |

| Ø | Conductor min. | 4.455 | mm |

| Conductor max. | 4.545 | mm | |

| Enamelled grade 1 min. | 4.549 | mm | |

| Enamelled grade 1 max. | 4.591 | mm | |

| Enamelled grade 2 min. | 4.592 | mm | |

| Enamelled grade 2 max. | 4.637 | mm | |

| Conductor nominal Ø | 4.750 | mm | |

| Conductor cross section | 17.721 | mm² | |

| Aluminium | Resistance min. | 0.0015 | Ω/m |

| Resistance max. | 0.0016 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 47.845 | kg/km | |

| Copper | Resistance min. | 0.0009 | Ω/m |

| Resistance max. | 0.0010 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 158.067 | kg/km | |

| Ø | Conductor min. | 4.702 | mm |

| Conductor max. | 4.798 | mm | |

| Enamelled grade 1 min. | 4.800 | mm | |

| Enamelled grade 1 max. | 4.843 | mm | |

| Enamelled grade 2 min. | 4.844 | mm | |

| Enamelled grade 2 max. | 4.891 | mm | |

| Conductor nominal Ø | 5.000 | mm | |

| Conductor cross section | 19.635 | mm² | |

| Aluminium | Resistance min. | 0.0014 | Ω/m |

| Resistance max. | 0.0015 | Ω/m | |

| Weight (only conductor, 2.7 g/cm³) | 53.014 | kg/km | |

| Copper | Resistance min. | 0.0008 | Ω/m |

| Resistance max. | 0.0009 | Ω/m | |

| Weight (only conductor, 8.92 g/cm³) | 175.144 | kg/km | |

| Ø | Conductor min. | 4.950 | mm |

| Conductor max. | 5.050 | mm | |

| Enamelled grade 1 min. | 5.050 | mm | |

| Enamelled grade 1 max. | 5.093 | mm | |

| Enamelled grade 2 min. | 5.094 | mm | |

| Enamelled grade 2 max. | 5.141 | mm | |

Find out more about our high-quality enamelled wires and our quality standards. Contact us today for personalized advice and a non-binding quote.

Sales Team

+49-5281-988-0sales@sh-wire.de

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)