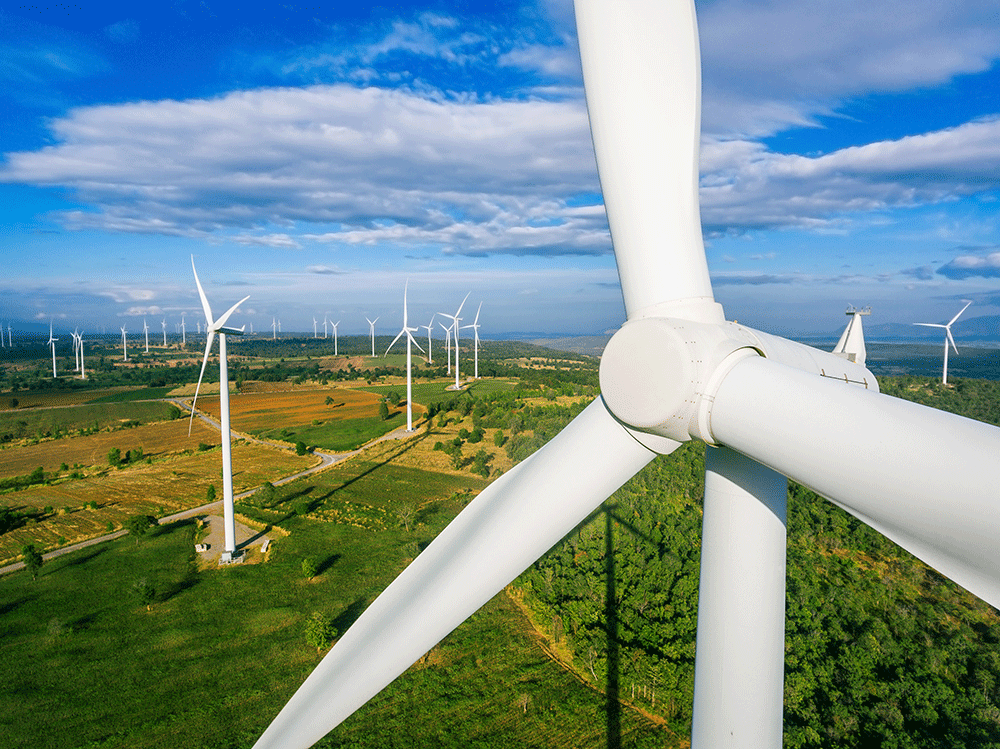

Drive Technology - we make the World move

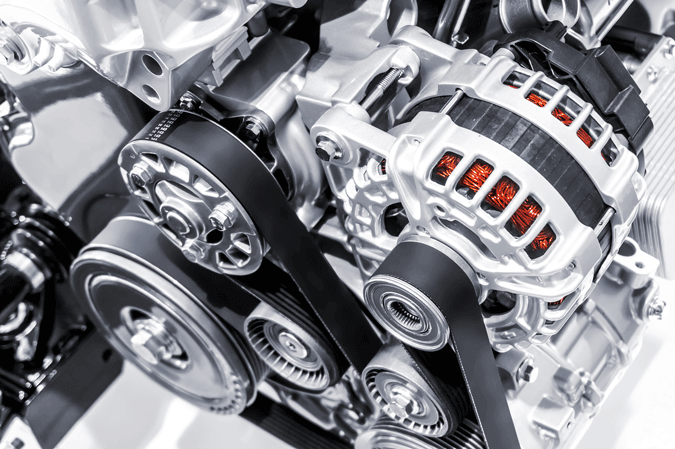

Decades of experience in drive and automation technology make us a partner to leading companies in the industry. Our enamelled copper wire enables the construction of efficient motors and conveyor systems and is tailored to the requirements of drive technology. Even if you need special wires for your project, you can rely on us.

Enamelled Wires of certified Quality

With our enamelled copper and aluminium wires we meet the highest quality requirements and with our innovative process monitoring we are taking a further step towards Industry 4.0. With continuous, fully automatic controls throughout the entire production process we are able to intervene quickly to regulate deviations. The patented system developed by us goes far beyond the industry standard.

In regular audits, we optimize internal processes and procedures and constantly increase our quality level. In addition to our products, we also keep an eye on our customers. We meet consistently high requirements for quality, product safety and legal compliance throughout the entire supply chain and are certified in accordance with IATF 16949. A clear benefit for you as a customer with demand for innovative enamelled copper wires.

Our enamelled wires for drive technology

SHTherm® 210

- High temperature resistant enamelled copper wire,

round, temperature class N - Excellent mechanical resistance to abrasion

- Extremely low coefficient of friction for gentle

wire processing - Verifiably improved strength of insulation

SHTherm® 210 Glide

- High temperature resistant enamelled copper wire, round,

temperature class N - Low friction functional coat for excellent windability at

optimized winding speed - Reduced machine contamination and lower mechanical stress

during winding process - Gentle wire processing due to reduction coefficient of friction

Our Know-how - Your Benefits

- More than 70 years of know-how in the production of enamelled wire

- Recognized innovation leader in the industry

- High-performance products for special requirements

- Customer-specific new developments

The standard for QM systems in the automotive industry IATF 16949:2016 defines the sector-specific requirements for series and spare parts production based on DIN EN ISO 9001:2015.

In the course of the annual certification SHWire has successfully passed the surveillance audit by the certification company DQS. For this purpose, processes of the QM system are continuously questioned, monitored, evaluated and optimized by the employees. Customer satisfaction is optimized by the continuous improvement of system and process quality. This enables us to meet the increasing demands on product quality, productivity and competitiveness and also to increase the performance for our customers.

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)